How can we conserve resources, reduce costs, and prevent accidents? This was the question engineer Emil Mauritz Hünnebeck asked himself in the early 20th century about his specialty fields: lightweight steel construction and industrial buildings. Born in Bochum, Emil Mauritz Hünnebeck wanted to be an architect even as a schoolboy and settled in Essen as a consulting engineer in the early 1920s, where he was appointed to the “Committee for Economical Construction.” On the committee, he also worked on the topic of “The ceiling as a load-bearing structure in the building.” His idea was that each component would be given multiple functions. And that, when selecting the ceiling form, the load-bearing structure should always be viewed as part of the whole building structure. With these basic ideas in mind, he set to work and came up with new construction methods – including the lozenge net technique (“Rautennetzbauweise”). This is considered the most important invention of his life’s work and was patented on August 20, 1924.

Lighter, cheaper, safer

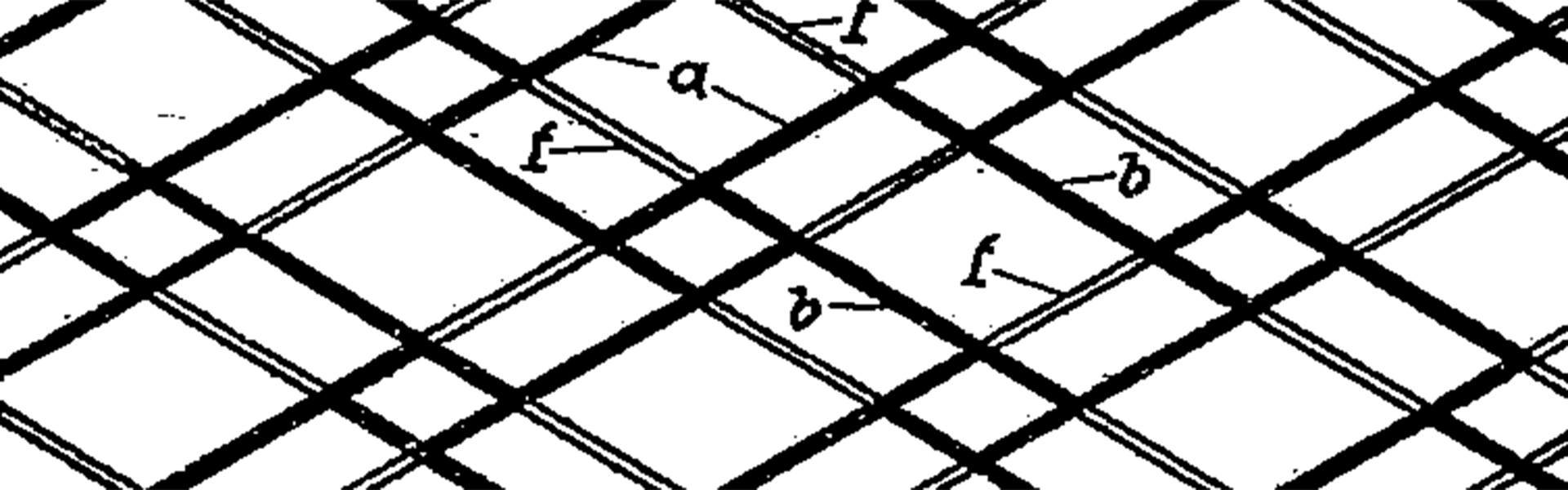

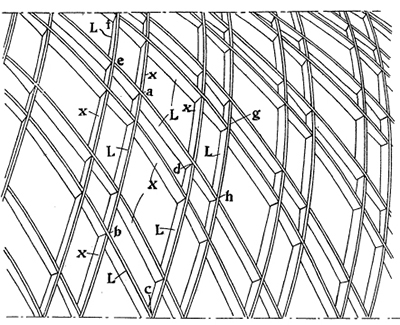

The principle behind the lozenge net technique is that there is only one main supporting element as a spatial load- bearing structure, the so-called “steel slat” (“Stahllamelle”). It is suitable for any span and for roof shapes with varying curvature. During Hünnebeck’s lifetime, the lozenge net technique was used for roofing water reservoirs, loading sheds, market halls, sports halls, exhibition centers, and station concourses. The technique was also helpful in church construction, as it adapted to the pointed arch design of the Gothic architectural style. Another advantage of the new construction method was a weight reduction of more than 25%. The slatted roof also scored highly in terms of costs, allowing savings of 25 to 30% compared to truss roofs.

During installation, workers could access the site from a scaffold and were therefore better protected from accidents. What’s more, the slats were comparatively light, weighing between 7.5 and 15 kilograms, and could be easily transported and processed. Emil Mauritz Hünnebeck founded Rautennetz GmbH in Essen in 1925 and a little later Deutsche Stahllamelle GmbH in Dortmund, which then merged with the Essen company. In 1937, Hünnebeck moved the company’s headquarters to Düsseldorf. Today, Hünnebeck Deutschland GmbH is headquartered in Ratingen.

(Header: from the patent application AT113209B)