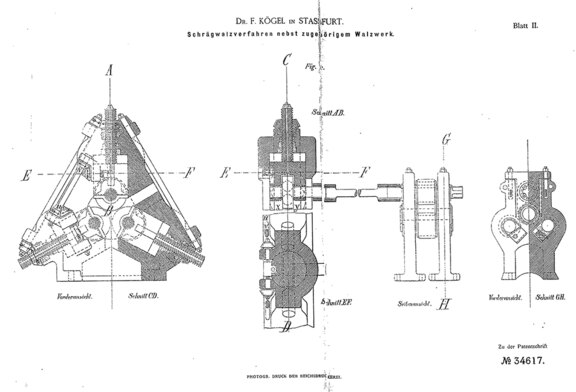

Iron files had been the specialty field of the Mannesmann company since 1776. When brothers Max and Reinhard joined their parents’ business in the late 19th century and got to know the work processes involved in file manufacturing, they brought with them a great deal of curiosity and eagerness to experiment. One day, they noticed that the polished round bars they used as blanks for their files displayed cracks and holes after being machined on smoothing rollers positioned askew. They attributed this to the inclined rollers. They began to use the principle systematically to produce pipes from a solid block of steel with the help of rollers. After some experimenting, they applied for a patent for the “piercing process” to produce seamless steel pipes in 1885. To manufacture pipes with an even inner surface, in the 1890s they combined the principle with what was known as the “pilger rolling process”: the hollow block was rolled into a long pipe with the required wall thickness by the back-and- forth motion of two rollers arranged one above the other and with the aid of a cylindrical mandrel. In 1891, the brothers were granted a patent for the “process and rolling mill for forming and calibrating rod- shaped bodies and plates using ‘pilger rolling’-like movement of the rolled piece”.

Two steps forward, one step back

Why is this called the “pilger rolling process”? The periodic rolling process and the movement of the pipe reminded the brothers of the “hopping procession of Echternach”, which takes place annually in Echternach in Luxembourg. Participants, or pilgrims – “Pilger” in German – “hop” through the streets of the town, two steps forward, one step back. The combination of the piercing and pilger rolling processes became established under the name “Mannesmann process”. This is still used today to manufacture seamless steel pipes.

(Header: tanantornanutra – Fotolia.com)