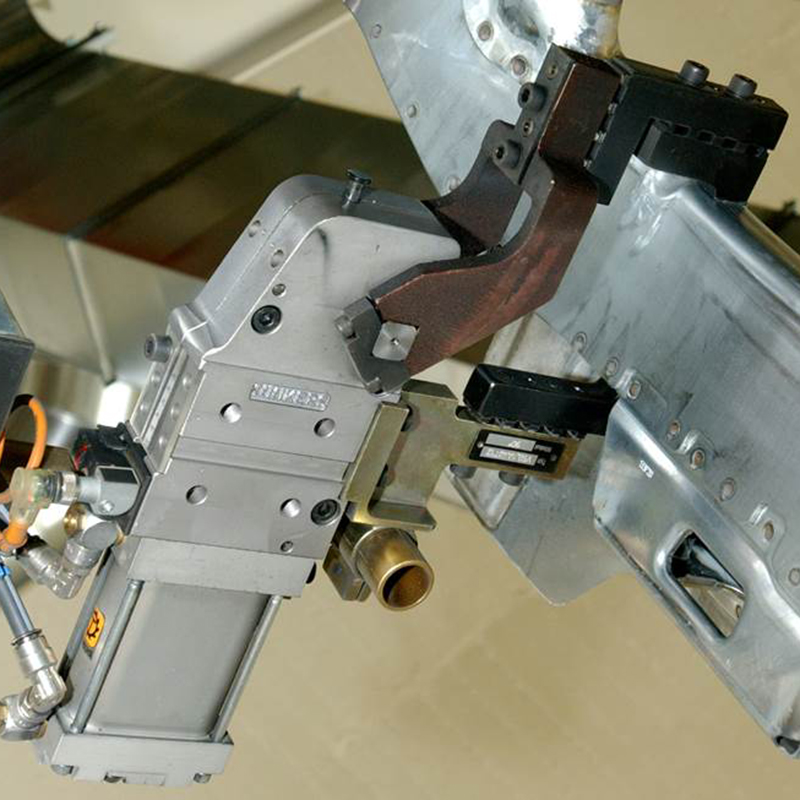

Sanitation and heating specialist Viega has a simple and safe solution for connecting steel pipes: the Megapress system. With this solution, the process is completed in just a few simple steps. The steel pipe is sawn off and any sharp edges removed, and the pipe is cleaned. The Megapress connector is then placed on the pipe and the press ring is attached. The Viega Pressgun makes the connection complete. The entire process leaves the steel completely cold, as no heat is used. This means there is no risk of fire. In addition, the installation time for the installer is reduced by up to 60% compared to welding.

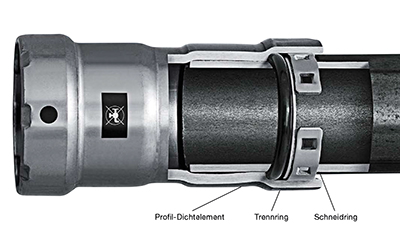

Megapress connectors feature a special profile sealing element, which encloses the pipe in three places at once, ensuring a tight connection even on rough surfaces. In addition, the connectors offer the special safety feature “Viega SC-Contur”, which ensures that unintentionally unpressed connections are noticed immediately during a pressure test and can be repaired.

And if you want to add another connection onto the pipe later? The Viega product range includes a press-in branch connector: it can be pressed into the pipe with the appropriate tools – a standard drill and a pressing machine. Installation is quick and energy-saving. Thanks to a profile gasket, the connection between the pipe and connector is permanently tight in around two minutes.

(Images: Viega GmbH & Co. KG, Video: Mechanical Hub)