Karl Schlecht was born with a trowel in his hand. The son of a master plasterer from Filderstadt in Baden-Württemberg, he studied mechanical engineering specializing in pump technology at the Technical University of Stuttgart in the 1950s and helped in his father’s business during vacations. Back then, plastering was backbreaking work. Plasterers had to carry the plaster on their backs in a vat and mix it by hand with a trowel. Various inventors had already tried to mechanize plastering. Karl Schlecht was the first to succeed: he designed a machine with a diaphragm pump and compressed air drive for his father’s business. The machine provided the young student with the topic for his degree thesis. Spurred on by this success, Karl Schlecht started his own business to produce plastering machines – KS- Maschinenbau – in 1958. The company was renamed Putzmeister Werk Maschinenfabrik in 1963.

Continuous mixing in a small space: the “Gipsomat”

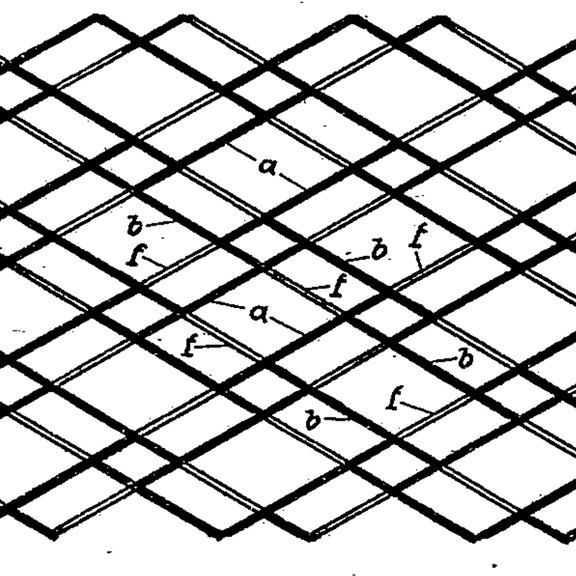

Continuous mixing in a small space: the “Gipsomat” called the “Gipsomat”. The basic idea behind the machine was that it could continuously mix the plaster in a small space as the plaster was supplied via a downstream pump. The correct quantity of the dry material automatically fell from the hopper when a constant amount of water flowed into the mixing tube via the pump. Removing the air from the powder gave the plaster a uniform consistency.

In addition to new types of pumps for ready-mixed concrete, the construction of truck-mounted concrete pumps with booms began with the opening of what is still the company site today in Aichtal in 1971. Further technical innovations were to follow. Putzmeister thus grew into the world market leader for concrete pumps, with numerous subsidiaries and branches worldwide. In 2008, the company helped to build the world’s tallest tower, the Burj Khalifa in the United Arab Emirates, by pumping concrete up to a height of over 600 meters.

(Image: rh2010 – AdobeStock)