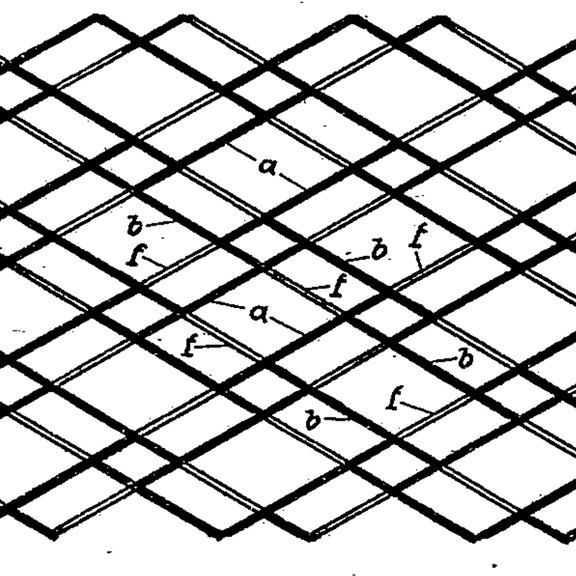

Whether for residential and commercial buildings, factories, bridges, tunnels, towers, or masts: reinforced concrete used to be the number one building material in Germany. But it had disadvantages. The production of reinforced concrete emits comparatively high amounts of CO2. What’s more, steel can rust. Dilapidated buildings must therefore undergo frequent and extensive renovations. Manfred Curbach, Chokri Cherif, and Peter Offermann from Dresden University of Technology did not want to stand for this and started to think about alternatives. The basis of their idea: carbon. The highly resilient and flexible material is already used in fishing rods, bicycle frames, vehicle construction, and space travel. From this material, the researchers created a new type of concrete composite material as part of a special research project between 1999 and 2011. A mesh made of fine carbon fibers that features excellent tensile strength and is significantly more resistant than reinforced concrete for use in a wide variety of applications. Its density is four times lower and its load-bearing capacity six times higher than that of steel. What’s more, carbon concrete does not corrode. The consumption of resources and energy, and thus CO2 emissions, in the production and maintenance of buildings are far lower.

Carbon concrete – lighter, thinner, more durable

Use of carbon concrete in the construction industry has been growing since 2006. By applying a thin layer, the lifespan of many commercial buildings, bridges, and façade elements has already been extended. New buildings benefit from the smaller size and lower weight of concrete components containing carbon: façade panels featuring carbon concrete, for instance, are only two centimeters thick – instead of eight centimeters like those with reinforced concrete. This reduces costs for production, transport, and assembly. To further investigate the benefits of and possible applications for carbon concrete, an extensive research project entitled “C3 – Carbon Concrete Composite” was launched in 2014. 140 institutes and companies are taking part in this project, which is financed by €45 million from the Federal Ministry of Education and Research (BMBF) and €25 million of its own funds. The researchers from Dresden University of Technology, who laid the proverbial foundation for this, were awarded the 2016 German Future Prize for their work.

(Header: robert – AdobeStock.com)